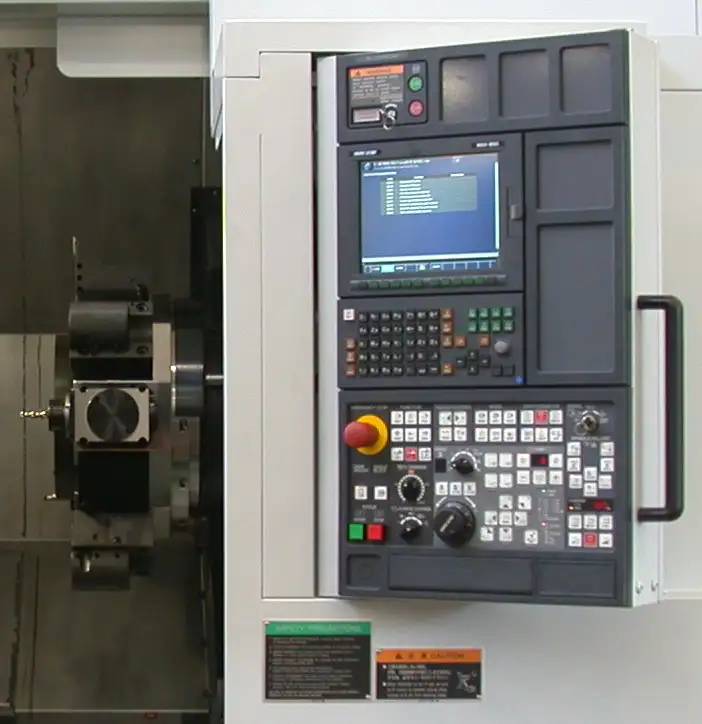

Are you looking to enhance your manufacturing process while keeping costs in check? Look no further than used CNC machinery. Used CNC machinery provides a cost-effective solution for manufacturers, offering the same precision and performance as new equipment but at a fraction of the price. Machine Shopper is committed to to providing you the most cost effective way of purchasing or selling used CNC machinery. But don’t take our word for it have a look at our current listings.

Investing in used CNC machinery can revolutionise your manufacturing process without breaking the bank. Inspection and refurbishment ensure these machines are in excellent working condition. With technological advancements, many used CNC machines offer the same features and capabilities as their newer counterparts. Used CNC machinery can handle various manufacturing tasks, from milling and turning to routing and grinding.

Not only does buying used CNC machinery save you money upfront, but it also reduces long-term costs. These machines are known for their durability and reliability, meaning they can withstand heavy use and require less maintenance. In addition, used CNC machinery depreciates slower than new equipment, allowing you to recoup a higher percentage of your investment if you decide to sell in the future.

Don’t let budget constraints hold your manufacturing process back. Unlock the potential of cost-effective precision with used CNC machinery.

Here at Machine Shopper we are committed to helping you directly connect with those businesses looking to buy the machinery you are selling or advertising used machinery you are looking to buy.

Advantages of using used CNC machinery

When it comes to improving your manufacturing process, used CNC machinery offers several advantages that can give you a competitive edge:

- The cost savings associated with purchasing used equipment are significant. Used CNC machinery is typically priced at a fraction of the cost of new machines, making it an attractive option for businesses with budget constraints. The savings can be particularly beneficial for small and medium-sized enterprises that may not have the financial resources to invest in brand-new equipment.

- Used CNC machinery also helps to reduce long-term expenses. These machines are known for their durability and reliability, meaning they can withstand heavy use and require less maintenance. Furthermore, used CNC machinery depreciates at a slower rate compared to new equipment. If you decide to sell your used CNC machines in the future, you can recoup a higher percentage of your investment.

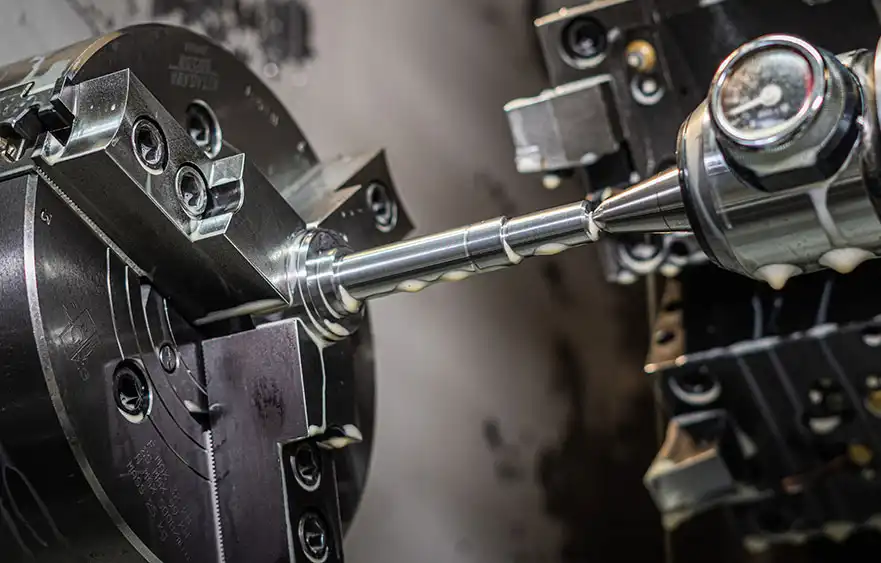

- Used CNC machinery offers the same precision and performance as new machines. These machines have been thoroughly inspected and refurbished, ensuring they are in excellent working condition. With advancements in technology, many used CNC machines offer the same features and capabilities as their newer counterparts, allowing you to achieve the accuracy and quality you need for your manufacturing process.

- Another advantage of using CNC machinery is its durability and reliability. These machines can withstand heavy use, making them ideal for high-volume production Additionally, used CNC machinery requires less maintenance than new equipment, reducing downtime and increasing productivity, helping you to meet production deadlines and deliver high-quality products to your customers.

By opting for used CNC machinery, you can achieve cost savings both in the short and long term. This cost advantage can give your business a competitive edge and allow you to allocate your resources more effectively.

Quality and reliability of used CNC machinery

When it comes to improving your manufacturing process, used CNC machinery offers several advantages that can give you a competitive edge:

- The cost savings associated with purchasing used equipment are significant. Used CNC machinery is typically priced at a fraction of the cost of new machines, making it an attractive option for businesses wiThe savings can be particularly beneficial for small and medium-sized enterprises that may not have the financial resources to invest in brand-new equipment.th budget constraints.

- Used CNC machinery also helps to reduce long-term expenses. These machines are known for their durability and reliability, meaning they can withstand heavy use and require less maintenance. Furthermore, used CNC machinery depreciates at a slower rate compared to new equipment. If you decide to sell your used CNC machines in the future, you can recoup a higher percentage of your investment.

Have you got unused CNC Machinery?

Then sign up today and register your Unsed CNC Machinery on the only peer-to-peerCNC trading platform

Factors to consider when purchasing used CNC machinery

Purchasing used CNC machinery requires careful consideration to ensure you make a suitable investment for your manufacturing process. Here are some factors to consider when purchasing used CNC machinery:

1. Machine condition: Inspect the used CNC machinery thoroughly to assess its overall condition. Look for signs of wear and tear, and check if any parts need to be replaced or repaired. If possible, request a demonstration to see the machine in action and ensure it performs as expected.

2. Machine specifications: Consider the specific requirements of your manufacturing process and ensure that the used CNC machinery meets those specifications. Look for machines with the necessary features and capabilities to perform your tasks.

3. Supplier reputation: Research the reputation of the supplier you are considering purchasing from. Look for customer reviews and testimonials to gauge their reliability and the quality of the machines they offer. A reputable supplier will have a track record of providing high-quality used CNC machinery and excellent customer service.

4. Maintenance and support: Inquire about the availability of maintenance and support for the used CNC machinery. Find out if the supplier offers servicing, repairs and technical support in case any issues arise.

5. Price and financing options: Compare prices from different suppliers to ensure you get the best value for your money. Additionally, inquire about financing options if needed, as some suppliers may offer financing plans to help make the purchase more affordable.

Tips for finding reputable used CNC machinery suppliers.

Finding reputable used CNC machinery suppliers is crucial to receiving high-quality equipment and excellent customer service. Here are some tips to help you find reputable suppliers:

- Research online: Find suppliers specialising in used CNC machinery. Look for suppliers with a robust online presence, informative websites, and positive customer reviews.

- Attend trade shows and exhibitions: Trade shows and exhibitions are great opportunities to connect with suppliers and see their machines in person. Take the time to speak with representatives, ask questions, and gather information about their products and services.

- Ask for recommendations: Reach out to industry colleagues and ask for recommendations on reputable used CNC machinery suppliers. Their firsthand experiences can provide valuable insights and help you narrow down your options.

- Check supplier credentials: Verify the credentials and certifications of the suppliers you are considering. Look for certifications such as ISO 9001, demonstrating that the supplier follows quality management standards.

- Visit supplier facilities: If possible, visit the facilities of potential suppliers to see their operations firsthand.

- Request references: Ask potential suppliers for references from previous customers. Contact these customers to inquire about their experiences with the supplier and the quality of the used CNC machinery they purchased.

Common misconceptions about used CNC machinery

Despite the numerous advantages of using CNC machinery, some common misconceptions may deter manufacturers from considering this cost-effective option. Let’s debunk some of these misconceptions:

- Lower quality: One misconception is that used CNC machinery is lower quality than new equipment. In reality, reputable suppliers thoroughly inspect and refurbish used machines, ensuring they are in excellent working condition. Used CNC machinery can offer the same precision and performance as new machines.

- Lack of warranty: Another misconception is that used CNC machinery does not have warranties. Reputable suppliers often provide warranties for their used machines, giving you added peace of mind and protection against unforeseen

- Limited capabilities: Some believe that used CNC machinery has limited capabilities and cannot keep up with the latest technological advancements. However, many used CNC machines offer the same features and capabilities as newer models, thanks to technological advancements.

- Higher maintenance costs: Used machines are known for their durability and reliability, requiring less maintenance than new equipment. Proper maintenance and servicing can keep used CNC machinery running smoothly and efficiently.

- Lack of support: Reputable suppliers offer maintenance, repairs, and technical support for their used machines, ensuring you have the necessary assistance to keep your machines operating optimally.

Maintenance and support for used CNC machinery

Maintaining and supporting used CNC machinery ensures its longevity and optimal performance. Here are some critical considerations for maintenance and support:

- Regular servicing: Schedule regular maintenance and servicing for your used CNC machinery to keep it in excellent working condition. Follow the manufacturer’s guidelines and recommendations for maintenance intervals and procedures.

- Train your staff: Provide training for your employees on the proper operation and maintenance of the used CNC machinery.

- Keep spare parts: Maintain an inventory of spare parts for your used CNC machinery.

- Utilise supplier support: Take advantage of your supplier’s maintenance and support services. They can provide technical assistance, repairs, and access to replacement parts, ensuring your machines perform optimally.

- Implement preventive measures: Implement preventive measures to avoid potential issues with your used CNC machinery. Regularly clean, lubricate, and inspect to identify any signs of wear or damage.

By prioritising maintenance and support for your used CNC machinery, you can maximise its lifespan and ensure that it continues to deliver the precision and performance you need for your manufacturing process.

Conclusion: Embracing the cost-effective precision of used CNC machinery

In conclusion, CNC machinery offers a cost-effective solution for enhancing your manufacturing process. With their comparable precision and performance to new equipment, used CNC machines can revolutionise your operations while keeping costs in check.

Investing in used CNC machinery can achieve significant cost savings both upfront and long-term. These machines are known for their durability and reliability, reducing maintenance costs and increasing productivity. Additionally, used CNC machinery depreciates slower, allowing you to recoup more of your investment if you decide to sell.

When purchasing used CNC machinery, it is essential to consider factors such as machine condition, specifications, supplier reputation, and maintenance and support. By following these considerations and finding reputable suppliers, you can ensure that you make a suitable investment for your manufacturing process.

Have you got unused CNC Machinery?

Then sign up today and register your Unsed CNC Machinery on the only peer-to-peerCNC trading platform